|

What is Iron Ore?

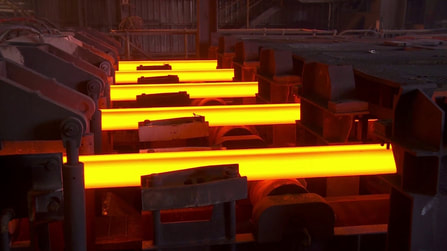

Iron ores are rocks and minerals from which metallic iron can be extracted. It is integral to the steel-making process and one of the most sought-after commodities in the world, accounting for approximately 95% of all metals used by modern industrial society. The most commonly used iron ore deposits are hematite (Fe2O3) and magnetite (Fe3O4). More than 90% of South Australia’s identified iron ore resource is magnetite. Magnetite iron ore requires processing before it can be used in blast furnaces and direct reduction steelmaking plants. However, its end products are typically of higher quality and are well sought after by steelmakers to increase productivity, provide efficiencies, and reduce emissions. The use of magnetite concentrates during the steel making process reduces greenhouse emissions by as much as 30% compared to hematite. Iron brought down the world’s first great civilization. Ours is built on its back. But the metal’s importance is far greater than that. Without iron, there would be no life. Without life, there would be no iron ore. Much of the ore being dug up in Australia was refined and concentrated by algae some 3700 million years ago. It was then crystallized through aeons of hydrothermal heat. Once people discovered how to turn it into steel, iron became a democratizing force. It is everywhere. It’s still the cheapest, most useful, and readily available metal we have.

Did you know?

The world uses 20-times more iron, in the form of steel, than all other metals put together. Where is Iron Ore mined in South Australia? South Australia has a number of magnetite projects either in production or exploration phase, including SIMEC Mining, which is expanding its magnetite operation in the Middleback Ranges, located on Narangga Land, Magnetite Mines which is progressing its Razorback Iron Ore Project in the Braemar Iron province, and Lodestone Mines who is also exploring in the Braemar province. Peak Iron Mines produces haematite iron at its Peculiar Knob site, with some residual magnetite and holds a Mining Lease for the Buzzard Project within the Hawks Nest Prospect. The Hawsons Iron Project at Broken Hill is also progressing and has been declared a Major Project by the South Australian Government, the Commonwealth Government and a NSW State Significant Project. The Whyalla Steelworks, operated by GFG Alliance, is a fully-integrated operation, starting with the mining of raw materials and ending with the distribution of finished steel products. Approximately 1.2 million tonnes of raw steel is produced in the steelworks each year, with about 65% of that product then transferred by rail to the steelworks Market Mills in billet form for further processing. The balance of the steel is then converted to finished products in the Whyalla Rolling Mill including steel slabs for construction and high-rise buildings and railway products. |